We Do Our Best for a Business Facing a Crane Distress

We are sure that most of you must have heard of the tragic incidence of Ethiopian airlines which crashed in 2019. Now, we are not going into the scrutiny of the incidence but taking it as a reference to express the importance of a “distress situation”. Some authorities and agencies had published that, the pilots had made a distress signal from the plane, and they were re-directed to land back by the Air traffic controller. The pilots didn’t get enough time to land the plane safely and unfortunately, a lot of lives were lost.

So, what exactly is a distress signal or a situation? A distress situation is a condition of being threatened by an imminent danger and calls for immediate assistance. A distress call takes utmost priority and should be handled by a person of authority and worked upon by specialists.

When it comes to material handling equipments like cranes, it is important that any such distress signals from the operators or maintenance teams should not go neglected. Cranedge was born out of such a commitment of attending any such material handling distress calls for any crane, any brand, anywhere around the globe. Cranedge team is of around 200+ such crane specialists possessing in depth knowledge of various material handling components for any brand or makes. The team, while rendering services to different customers, has also meticulously compiled data of over 35000+ cranes of different makes, transforming it into a large ‘Knowledge Bank’. Thus, we are equipped with all the essentials required to address any material handling related distress calls. One such distress situation is discussed below:

Distress Signal: A Case Study!

A major renewable energy sector company faced a distress situation in the year FY 2015-16. Their plant caught a sudden fire that consumed all of its inside machinery and severely damaged the over cranes as well. The company had commitments towards their customers, and they could not afford to stay sedentary for long. The customers production team was committed to restore back its full production at the very earliest. The entire team at the wind energy producing unit was determined to rebuild the facilities in the shortest possible time and immediately start production. Whatever was to be ordered under Capex, was immediately taken up.

EOT cranes play a vital role in the manufacturing process of blades and towers, as expressed in our previous blog (Wind Energy)

Operating without the cranes was an impossible task. Considering this aspect, reinstalling the cranes was among the top priorities for the company. For this, they had two options – the first was to order completely new cranes, and the second was to explore refurbishing the existing damaged cranes. Considering the condition of the damaged cranes, the client’s production team wanted to rule out the refurbishing option. While assessing the delivery period of the new cranes, they realized that it would take at least 10 weeks of time to manufacture the cranes & start installation at their site. 10 weeks was a drastically long period given the tough situation. In order to meet their delivery commitments to their customers, it was imperative to start production within four to five weeks (maximum).

Thankfully, the manufacturing unit had an AMC for all their cranes with industry experts, Cranedge. Team Cranedge was at site immediately, to assess the damages. While assessing the extent of the damage to the ten cranes, they found that all the cranes were severely damaged barring the steel structure, which needed some modification & painting. Rest all the electrical, hoisting machinery, control circuits were rendered useless. They also understood the dilemma of the customer about being unproductive for long as the end clients were getting hampered.

Our Solution!

The open option for the Cranedge specialists was to refurbish and restore the damaged cranes. Was it Impossible? Not for Cranedge! An urgent meeting with all global network suppliers was called upon at the Cranedge HO and was requested to co-operate and supply the crane kits, electricals, cables & all necessary spares at the earliest. Plans were chalked out, engineers were sanctioned at the distressed plant, schedules were set, and the workforce was planned to start work at the site, round the clock. The parent company, ElectroMech, stepped in to look over the situation & provide assistance wherever required. All necessary spares were despatched on a war footing. The excellent coordination, perfect planning, and hard work of our dedicated team yielded results on Day 15, and four cranes were made operational. The remaining six cranes were also brought to normalcy with equal diligence and speed within the next 15 days.

All the refurbished ten cranes were duly load-tested, certified by authorities & handed over for production within 30 days, as assured by team Cranedge. The production at the manufacturing unit begun operations in full swing.

The customer still has goosebumps when he remembers the situation, but also extends a heart-felt thank you to the members involved from Cranedge – Ultimately, customer satisfaction is the final goal!

A classic example of how the Cranedge team responded to a distress situation! This case deserves special attention from all our readers, that no matter how small or big the distress signal, responding and attending to the situation is the only way forward.

If you feel, your cranes and related material handling equipment needs a ‘specialists’ eye’ to see through the odds, then we are just a call away!

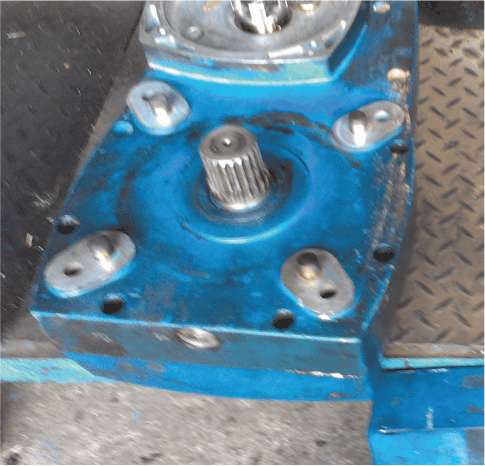

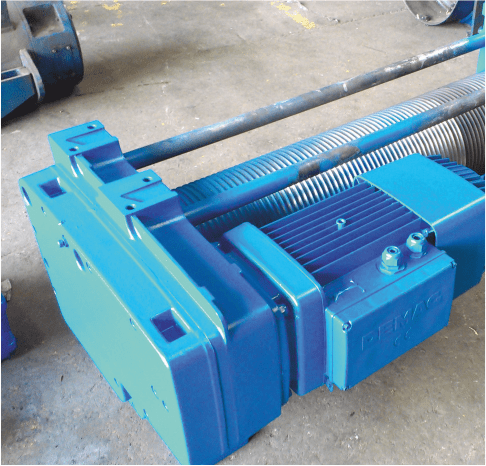

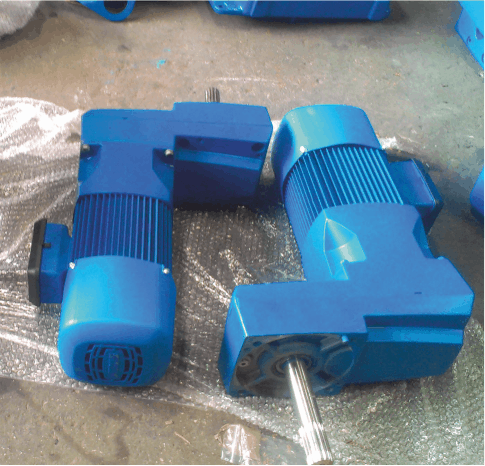

| Before | After |

|---|---|

|

|

|

|