Must-Have “Safety Enhancers” for Cranes!

Safety is the key to ensuring an accident free workplace. Though the cranes are manufactured keeping all the safety parameters into consideration, there are products, strategically developed, which further enhances the safety of the equipment and the operator. These safety enhancers try to nullify human errors and reduces the chance of any major mishap due to human negligence.

Cranedge has an array of products and services that help ensure safe, smooth and hassle-free operations of your cranes. These products can be easily be fitted to your existing cranes to experience many new advanced features. They allow the operator to master complete control over the equipment and enhance its performance

The following are an array of safety enhancers offered by Cranedge to our industry:

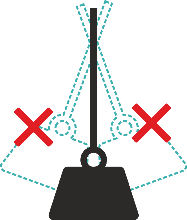

1.Sway Control

A swinging load can pose a serious threat to the safety of the work force as well the plant machineries. “Sway Control” as the name suggests prevents the free-swinging of the load when the crane is travelling with loads suspended under the hook and keeps them very stable while lifting and traversing. This is obtained by the usage of special components like encoders & a closed-loop system which detects the exact position of the hook & the suspended load under it thereby controlling the swaying of load. It also drastically reduces the time spent in stabilizing the loads, making it a must-have a feature with great benefits for your cranes having a higher height of lifts and larger size loads.

2. Anti-Collision

In several factories, multiple cranes operate simultaneously in the same bay. There can also be a scenario wherein the cranes are installed at different levels in the same bay. This always poses a threat of two cranes colliding with each other due to an error in the judgment of the crane operator. To avoid any such threats, Cranedge offers you the right solutions, with an appropriate Anti-Collision device. The transmitter–reflector duo work in unison with precision, thereby automatically detecting the safe distance, that needs to be maintained in between the two cranes. These sensors can also be synced with flashing alarms to alert the operator of a possible situation.

3. Anemometers & Crane Anchors

Outdoor duty cranes often have to bear the brunt of nature’s wrath. Be it heavy rains or strong wind forces, ElectroMech cranes are designed to stand tall in these extreme conditions. To ensure that during adverse conditions, when crane operation is not safe, Cranedge offers solutions such as “Anemometers” which can detect high wind speeds & trigger an alarm system in the cranes, hinting the operators about halting the material movement, as the conditions may not be safe.

Furthermore, as these cranes are usually gantry cranes used for various construction & infrastructure projects, crane anchors can be used on these cranes. A Crane anchor is a locking mechanism that is fabricated to the crane structure & it holds the crane firmly to its ground. It prevents the cranes from toppling and avoids serious damage to property and life.

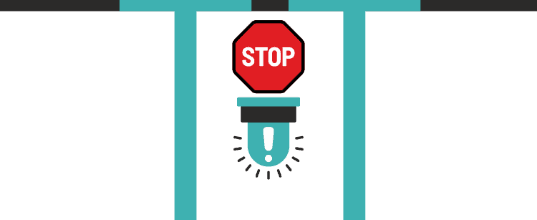

4.Human Sensors

Human sensor is an extremely precise piece of equipment mounted on some specific cranes & related material handling products. Unlike the overhead cranes, the human sensors are fitted on ‘legs’ of gantry cranes or semi-gantry cranes, transfer carts or vertical mast of stacker cranes. These sensors can detect any person or object in its path. Once activated, they immediately actuate the brakes thereby stopping the crane.

5.Slip Ring to Squirrel Cage Motors

Several conventional cranes, especially those which are more than a decade old, were fitted with slip ring type motors. Technology has evolved but the industry still uses the old technology as the procured equipment was built as an asset. Replacing the slipping motors with squirrel cage motors offers several advantages. The most significant of them is that squirrel cage motors can be easily paired with VFD (Variable Frequency Drive). By using the VFD controller, you can experience the following advantages:

- Smooth start-stop, settable acceleration and deceleration values

- Flexibility in setting micro speed.

- The jerk-free transition from micro speed to full speed.

- Brakes get applied at almost zero speed.

- Enhanced life of brakes and crane brake liner

- Ease of connection with other devices within the universal communication protocol

Cranedge has developed an expertise in the replacement of slip ring type motors of several cranes with squirrel cage motors and the customers are experiencing enhanced productivity along with other additional benefits.

6.Load Limiter Display

A load limiter is a safety device that prevents unintentional overloading of EOT cranes, hoists, and winches. A load limiter prevents lifting of the load in the event of overloading (exceeding the safe working load of the crane) and at the same triggers an alarm, making the operator aware of the situation so that necessary steps can be taken to avoid a major mishap.

7. EMote

EMote – A unique feature with hosts of benefits from the cluster of offerings from Cranedge. EMote offers remote diagnostics of crane health and remote support for maintenance. Various sensors and condition monitoring devices fitted on the crane collect and transmit data in real-time & with the facility to store data on cloud/servers. Such data can be easily accessed by the customer and the Cranedge specialists through a portal to make an informed decision about maintenance & upgradation in the crane. Promptly attending to such maintenance issues helps in improving productivity and safety at the workplace.

Thus, to conclude, the above-discussed safety enhancers can be viewed as a boon for any workplace in many ways but the most significant advantage of having them will be to increase efficiency and productivity along with safety on the shop floor.