Project challenges

Emerson’s Pune plant had an old 5t Single Girder crane which was procured a few years back from a European crane manufacturer. With the changed requirements of the manufacturing activity, this crane was not being actively used and was lying idle. At the same time, the company’s foundry in Coimbatore required a similar crane for handling heavy moulds of large-sized castings. For reusing the asset in one plant to meet the requirement of another plant, the Emerson team thought of relocating the crane.

However, the span available at the Coimbatore foundry was shorter compared to the span of the existing crane. Also, the LT rail available at the Coimbatore foundry was of 60lbs, different from that of the Pune factory. Hence, there was a need for different size of LT wheels. Procuring them from the original manufacturer was a costlier proposition. The Emerson team wanted Cranedge to undertake the complete responsibility which included, modification, transportation to Coimbatore, erection and commissioning of the crane.

The original crane manufacturer was unwilling to take up the job or supply only modified LT wheels.

Solution from Cranedge

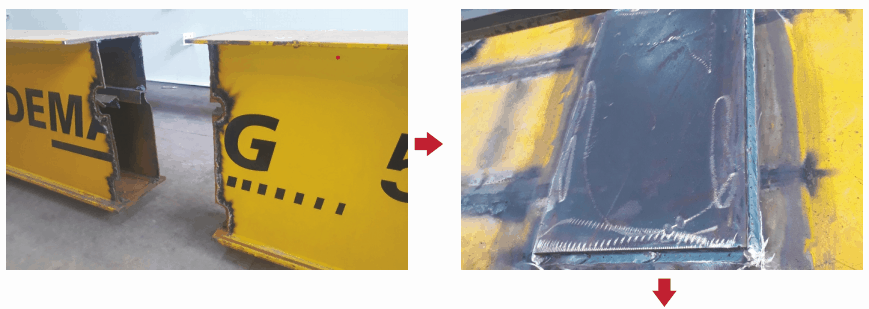

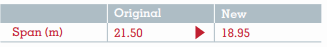

The Cranedge team inspected the new site at the Coimbatore factory, as well as carried out a thorough inspection of the existing crane. After a detailed study, our team proposed to reduce the span of the crane by cutting the main girder.

The customer sent the dismantled crane to the Cranedge factory, but to save the transportation cost, it was cut into two

halves using ordinary gas cutting. This caused a damage to the girder and Cranedge specialists had a daunting task to

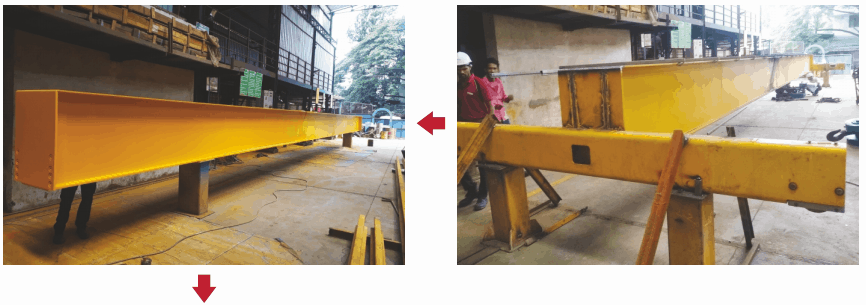

utilize the same girder without any increase in the project cost. Cranedge team altered the span and rejoined the girder with splice joints. This ensured reduced girder length without compromise on the strength and safety of the crane

Another major task was to modify LT wheels to make them suitable for the 60lbs LT rails. This was achieved by increasing the tread width. Additional guide rollers have been provided to avoid excessive wear of wheel collars.

The entire repair work and painting were carried out in the Cranedge factory and then despatched to the site. The

project was completed in just 10 days’ span. Subsequently, the erection and commissioning work was also handled by the Cranedge team.

Benefits to Emerson

- Efficient reuse of the existing asset which was lying idle

- Emerson saved a substantial cost involved in procuring a

new crane for the Coimbatore factory - Considerable time saved as the project was treated as

‘Top Priority’ - Ingenious solution to modify LT wheels which not only

saved cost, but also time as well - Safety assurance from the crane experts

Emerson, headquartered in USA, is a global manufacturing company that brings technology and engineering together to provide innovative solutions for customers in industrial, commercial and consumer markets around the world. Emerson helps manufacturers through the industry’s broadest portfolio of technologies to measure, control, optimize and power their operations. Emerson Process Management India Pvt. Ltd. (Virgo Valves) is a leading supplier of process management products and solutions, including control valves, regulators, transmitters, analyzers, and automation systems.

The company has a well-equipped plant at Hinjewadi, near Pune and serves various industries including automotive, food & beverages, marine, power, oil & gas and process plants. They also have a modern foundry in Coimbtore which manufactures castings required by various manufacturing plants in India.

Expert aftersales support for